+86-15221358017 / 15221358018 /15221358066/15021994930 info@purilaser.com

ADDRESS

Views: 526 Author: Site Editor Publish Time: 2018-08-28 Origin: Site

1,Installation Requirements

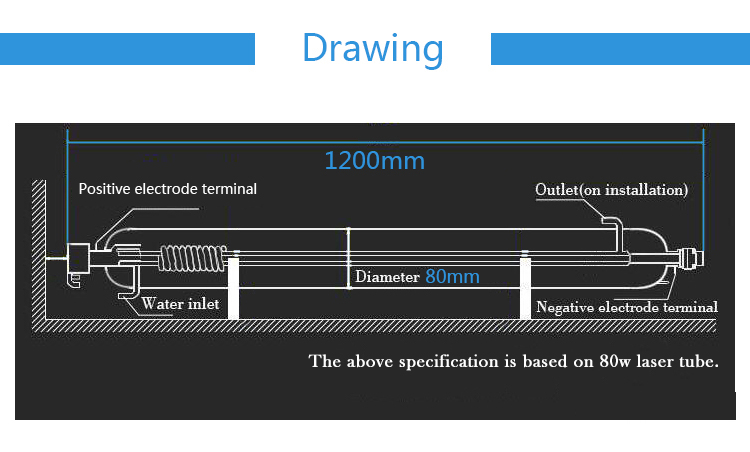

Laser tube should be Strictly installed according to the installation diagram, it’s equipped with a dedicated power supply, positive pole is with high voltage, and the starting voltage is 24 kV !

Adverse consequences caused by failure to installation: inner tube breakdown by striking arc , and result in a leakage.

2,operating conditions

Water cooling: cooling water is pure water, the flow rate is 3-5 liters per minute, and the standard water temperature is about 30 degrees.

Use environment: temperature 2-40 degrees; humidity 10-60%

Working current: The detection current

The maximum working current should be controlled below 30MA.

The long-term working current must be controlled below 28MA,

The optimal working current is 18MA. Under this working current, the laser tube has the longest lifetime.

The above current requirements must be based on the actual current of the ammeter connected in series on the female line.

The undesired consequences of not using it as required: The negative electrode will appear brownish yellow when used for long-term over current, and the life of the laser tube will be greatly shortened.

3,Working Performance

Laser tubes can cut and engrave,it can be converted to each other.

4,Safety notes

Please must wear protective glasses when adjusting CO2 laser tube, because laser tube emits invisible light.Please notice security IDs.The positive pole carries high pressure.

5,Storage and transport instructions

Please let out completely coolant for storage and transport.Low temperature turns the coolant to ice, which makes laser tube be broken.The environmental temperature should be 5-40 degrees, and humidity 10-60%.

6,Note:

Do not wipe mirror frequently, or laser power down,and mirror broken.Observe the following ways to clean mirror correctly.

1.Do not use laser tube when mirror is dirty.

2.air bag with oblique rotating mirror

3.Use the Syringe to extract the pure alcohol to spray the surface of lens.

4.Please use laser tube as the effect of the alcohol wears off.

Please far away output mirror 300mm when you test beam quality on plexiglas to avoid mirror damaged.。

7,Common malfunctions and solutions

1:Cause and solutions of weak laser power

(1) The incorrect position of support stand; solution:at the 1/4 point of laser tube from both ends.

(2) The optical route or the focus position is deflected;

Solution: adjust optical route of laser machine, make the focus point on the top surface of the material.

(3) Lens at output of laser tube or mirror & lens of laser machine is dirty.

Solution: Improve working environment, keep mirrors and lens clean.If mirrors and lens are dirty,please ask professional technician to clear the output lens with alcohol or obliquely blow the dust on lens and mirrors by

(4) Laser tube use up; Solution: change a new laser tube

2:Cause and solutions of tube burst during working time

(1): Machine water cooling system break,No water or little water cause the burst of laser tube.Solution:Change laser tube and machine water cooling systm(2) power supply break,Without work signal,laser tube also work can cause the burst of laser tube.

Solution: Change laser tube and power supply

(3) High voltage terminal or wire splice of laser tube ignited cause Burst of laser tube.

Solution: Make the High voltage terminal at least 10cm from iron body, keep high voltage

wire splice at list 5cm from iron body and make it under insulation protection. If there have no 5cm range, please use the insulating material to isolate, for example rubber, wood..etc

(4)Too hot water and too cool water and very hot mixed very cool water in water cooling system

cause laser tube Burst

Solution: keep the water in water cooling system or water chiller from 20-30 ℃ ,it will lengthen the lifetime

Note: Water freezing, water temperature over 50 ℃,too cool water mixed too hot water is prohibited in water cooling system and water chiller.

(5)Water is so dirty that left much precipitate in laser tube body cause laser tube burst.

Solution: Keep water in water cooling system or water chiller clean.

3:Laser tube Strike fire

Laser tube high - voltage cable joint or high - voltage end must be connected well, you can weld and add insulation if need. The high pressure end of the laser tube or the high pressure wire connector shall be at least 5cm away from the metal material , If less than 5cm, it is easy to cause the high-voltage end or high-voltage wire connector to spark, leading to damage of the laser tube, And now, you must be add insulating material on the metal all round (rubber, Acrylic, wood .etc) undertake partition, in order to prevent spark.

Note: If you not follow these instructions, will not enjoy compensate under the warranty.