+86-15221358017 / 15221358018 /15221358066/15021994930 info@purilaser.com

ADDRESS

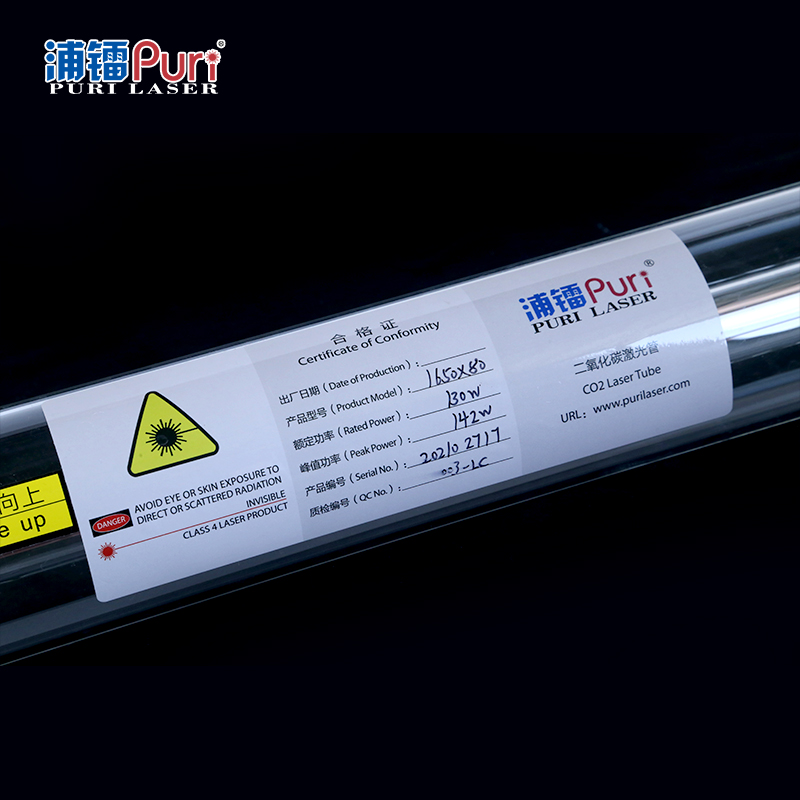

Views: 93 Author: Site Editor Publish Time: 2022-04-07 Origin: Site

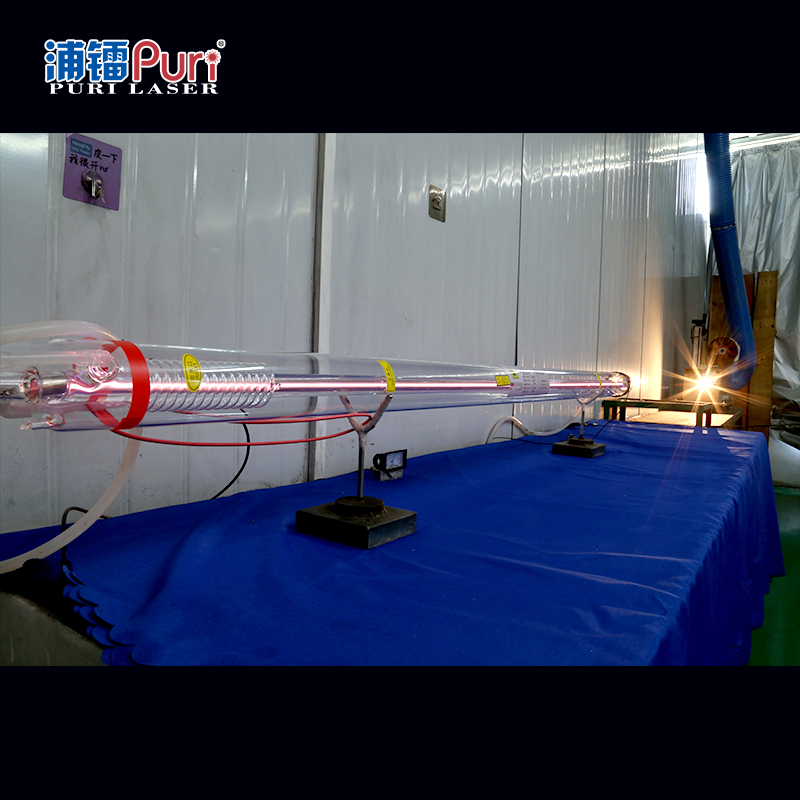

Installation method of glass CO2 laser tube

1: When using, please connect the cooling water first, adopt the principle of low in and high out, adjust the position of the water outlet pipe to ensure that the cooling water is full of the cooling pipe, and there can be no bubbles in the pipe, and then turn on the power. Requirements: Use soft water (distilled water or pure water) for cooling water, and pay attention to the water temperature of cooling water. The cooling water should be replaced in time or stopped for a period of time; the cooling water in cold areas should not freeze, especially after the laser is stopped, the cooling water should not be stored in the laser tube to prevent the cooling water from freezing and causing explosion. (Special attention: users who use AC power, the cooling water tank must be grounded).

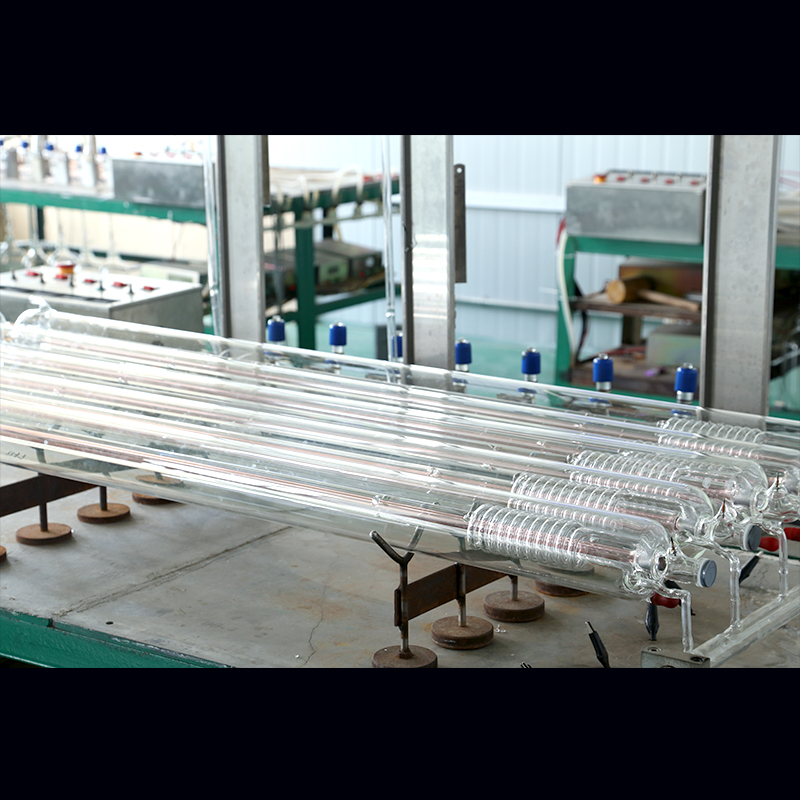

2: The two support points of the laser tube should be at the point of 1/4 of the total length of the laser tube to ensure that the flow of cooling water is 2L-4L/min; otherwise, the effect is not good, it will cause mode jumping, and the spot will change to several points, resulting in power Down; the cooling water return port must be covered with water in the water tank, otherwise the cooling water in the laser tube will not be filled every time the machine is turned off.

3: Pay attention to protect the output window of the laser, avoid the smoke generated during the working process (including the process of debugging the optical path) from sputtering to the surface of the output window, to prevent the outer surface of the output window from being polluted, and the power will drop. At this time, absorbent cotton or silk cloth can be used. Gently wipe the outer surface of the output window with anhydrous alcohol.

4: During the debugging process, adjust the laser support point or rotate the laser orientation to achieve the best output effect, and then fix the laser.

It is important to note:

1. Avoid accumulating dust near the high-voltage electrode, keep it dry, and keep the high-voltage end as far away from the metal as possible to prevent high-voltage ignition and discharge.

2. During the use of the laser, no scale should be formed in the cooling pipe, so as to avoid blockage of the cooling water and poor heat dissipation effect. Once found, the cooling pipe can be cleaned with 20% dilute 3. hydrochloric acid to remove scale.

4. The laser is made of glass and is fragile. When installing and using, avoid local stress.