+86-15221358017 / 15221358018 /15221358066/15021994930 info@purilaser.com

ADDRESS

Views: 101 Author: Site Editor Publish Time: 2022-01-05 Origin: Site

How to clean the dirt inside the laser tube

After working for a period of time, there will be a lot of dirt on the wall of the laser tube water casing pipe and the water pipe. This is caused by the long-term use of the laser tube, the dust, the deposition of cutting materials, and the reproduction of microorganisms. These dirt attached to the tube wall will affect the cooling water can not take away the temperature in the laser tube, causing the laser tube power and luminous spot to be affected, and even cause the laser tube to burst in severe cases.

In this situation, we recommend using a chiller and regular maintenance according to the following content, as follows:

Check the level of the coolant in the water tank of the chiller: It is recommended to check once a half month in summer, and once a month in winter. If the cooling water level is found to be less than 60% of the total volume, please add water in time (the water should be soft water or Distilled water; completely replace the cooling water every two months. Check the condition of the chiller condenser; replace the new deionization filter and cooling water filter every five months to remove dust and debris from the high-voltage power supply and the chiller .

If the inner wall of your laser tube has been contaminated, please clean it as follows:

1. Make sure to remove the positive and negative connections of the laser tube and the cooling water inlet and outlet pipes when the power is off.

2. Empty the cooling water in the water cooling tube of the laser tube, and seal the output end of the laser tube with tape to avoid water pollution output during cleaning.

3. Debug the hydrofluoric acid solution, the debugging ratio is 1:1000 (hydrofluoric acid: water), and pour the adjusted aqueous solution (or use glass cleaning agent) into the laser tube cooling tube until it is full.

4. Place the flat surface and wait for 30 minutes, shake it evenly after placing it, and release the aqueous solution after shaking for 3 minutes.

5. Rinse with a lot of water after emptying to avoid the aqueous solution from corroding the glass. If there is still a large amount of dirt that has not been cleaned off, you can repeat the previous cleaning method. The soaking time should not exceed 30 minutes. Rinse with water immediately after soaking.

6. After cleaning, use water-absorbent materials to wipe off the remaining liquid on the outside of the tube wall, light outlet, and high-voltage end. Take care to avoid wiping and damaging the electrode column of the laser tube.

7. After removing the sealing tape at the output end of the laser tube to ensure that there is no pollution to the lens or blocking the laser lens, install the laser tube according to the installation process.

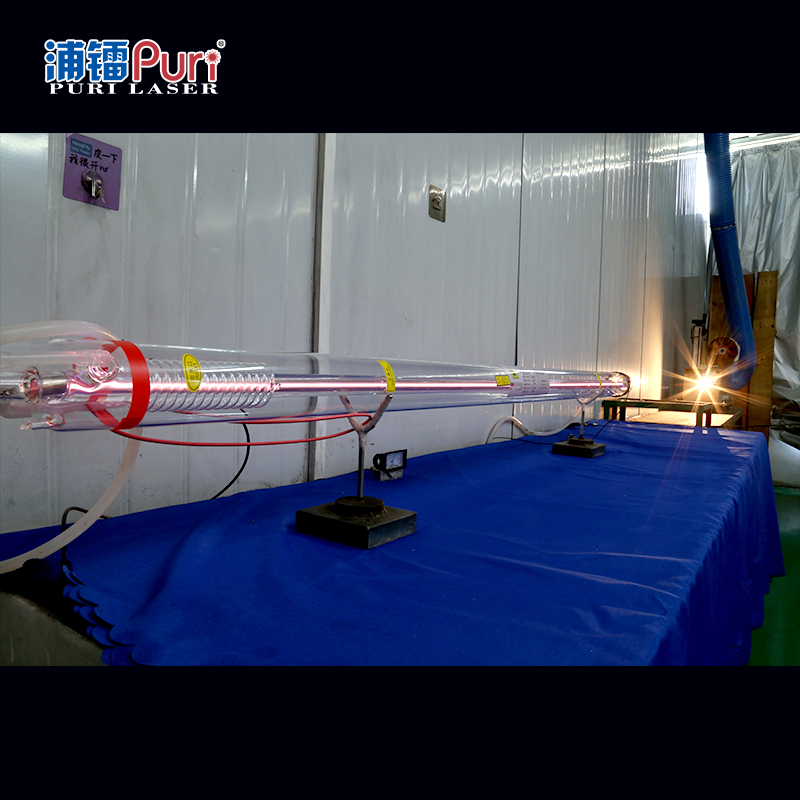

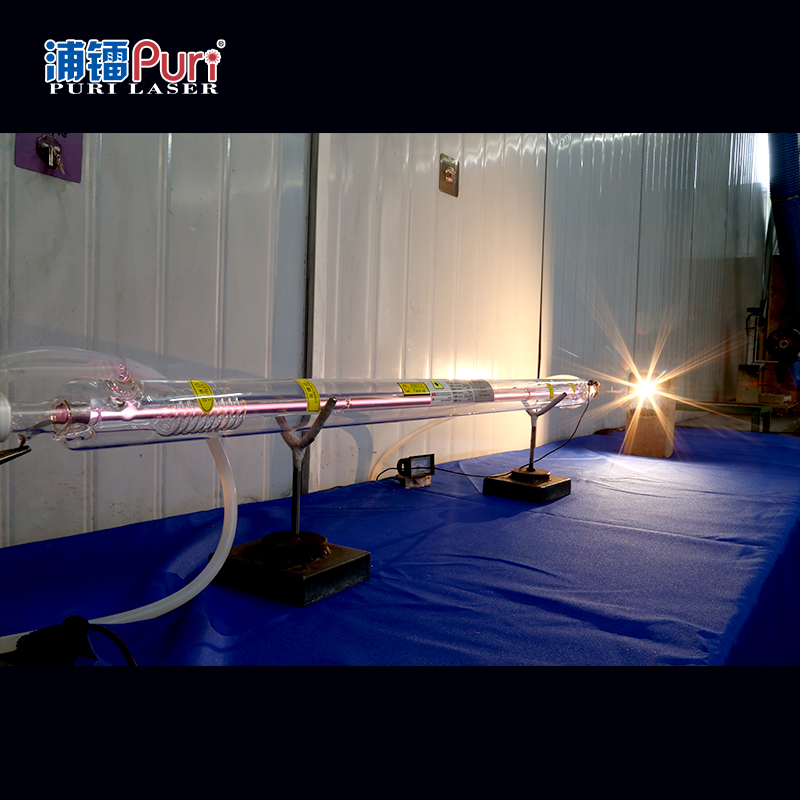

80W LASER RUBE

80W LASER RUBE

60W LASER RUBE

50W LASER RUBE